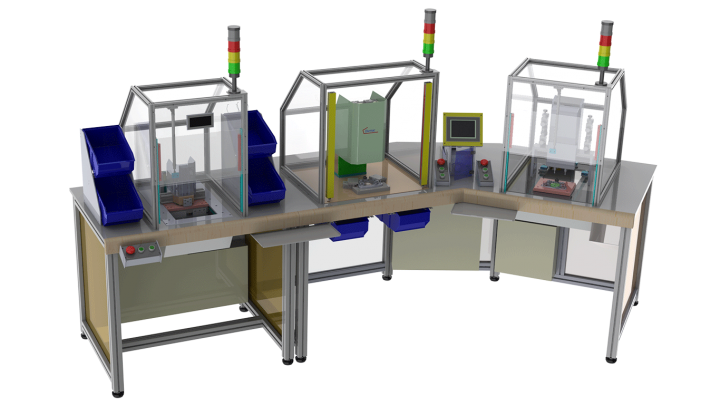

REACTION PLATE

ASSEMBLY - LINES

Equipment developed for spring assembly and ultrasound welding. Its main objective is to check airbags. It has a console for parameters introduction.

Workstation 1 (Spring assembly U type):

- U-spring automatic assembly

- Spring force checking and 2 helical springs assembly

- Shield for operator protection

Workstation 2 (Ultrasound Welding):

- Plastic pins detection

- Contour sensor (verification of anomalies in the welding tracks)

- Protection barriers

Workstation 3 (Verifications):

- Continuous verification and OK warning

- Measurement of contacts opening

- Welding and components verification by camera view

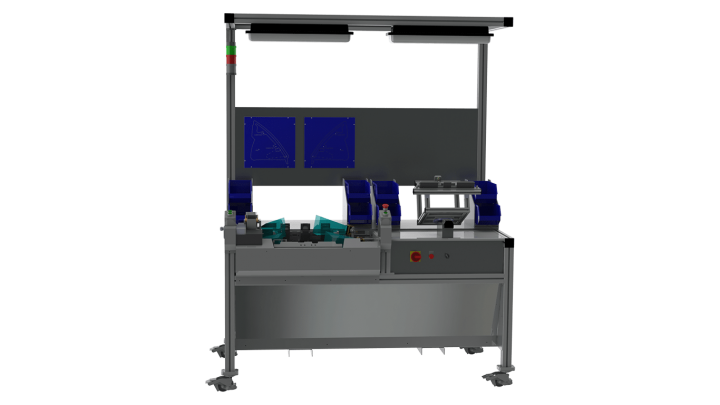

GLOVE COMPARTMENT AXLE

ASSEMBLY – WORKSTATION

Equipment conceived for assembly and final checking of the right and left glove compartment axis.

- Automatic assembly of the metallic axes

- LED’s panel for error identification transmitted by view camera

- Verification of components through cameras

- Bimanual control for operator’s protection

- Manual assembly for shock absorber and stoppers

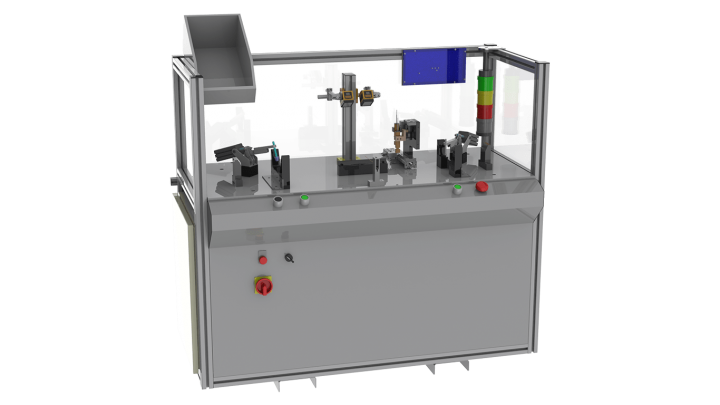

IRUE PANEL

ASSEMBLY - WORKSTATIONS

Equipment designed for assembly and verification of 3 sensors.

- Operator’s intervention in the beginning and end of the operation

- Components are manually inserted in the equipment

- Verification of well assembled sensors through infrared vision cameras

- Verification of the version of the piece

- Ok warning along with hot points according to the version

- LED’s panel for error identification

MOLDING ASM-WS SI

ASSEMBLY - WORKSTATIONS

Equipment specially designed for assembly and component verification.

- It works with an operator and pieces supply is ensured by a robot or two operators will ensure it manually

- 2 linked structures that can be separated when the equipment is being handled by 2 operators

- Safety barriers with an operator

- Bimanual control in case of having 2 operators

- Injection channel cut

- Insertion of metallic clips in the pieces

- Bimanual control regarding operator’s protection

- LED’s frame for error identification

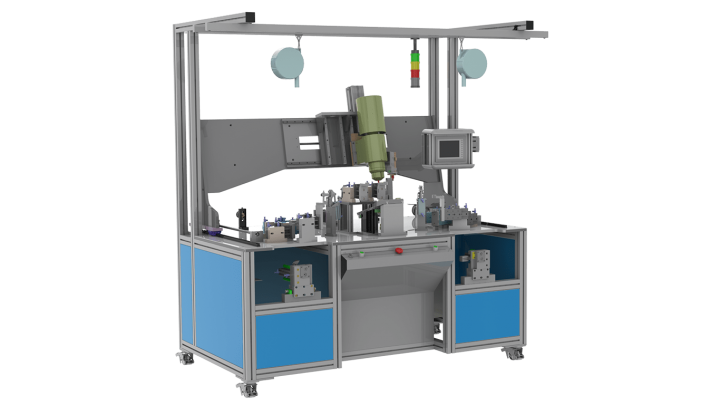

FRONT END PASSAT COUPÉ

ASSEMBLY - WORKSTATION

This equipment has been designed with a specific purpose: put metallic rivets on the plastic front of the VW Passat Coupé car.

- This is operated with pneumatic riveting tool

- Riveting tool operates with movements in XYZ axis regarding metallic rings with flaps to beading

- Metallic clips introduction

- Check the right placement of all elements

- Programming console where further steps can be seen

- Bimanual control regarding operator’s safety

- Eletric and pneumatic movements

ASM-LPLR PANEL

ASSEMBLY - WORKSTATIONS

Equipment designed for metallic rings introduction through nailing.

- Metallic clips introduction

- Metallic bushing nailing

- Torque limit screwdriver

- Verification of all assembled components

- Safety barriers regarding operator’s protection

- Ok mark on the piece

- LED’s panel for error identification

- Operator’s intervention in the beginning and end of the cycle