Based on sustained growth and increased experience in other industries, Divmac also develops healthcare solutions through a set of specific customer needs.

SURGICAL GOWN

ULTRASOUND WELDING

Equipment developed regarding surgical gowns production by ultrasound welding.

- Ultrasound welding

- Parameterization console that controls de quantity of pieces per lot

- Cycles number count

- Folding tape

- Continuous welding with tape traction system

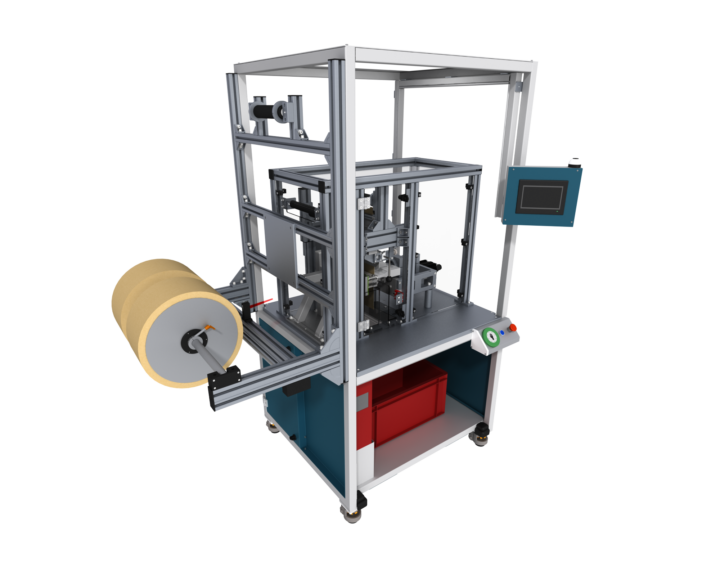

D-UWT

ULTRASONIC WELDING TEXTIL

The Ultrasonic Welding Textil, D-UWT allows you to program the size of the fabric to be cut or weld, being completely flexible in process and parameters of the cutting and welding, it can create different types of products according customers needs. It is possible to create more than 20 references, changing the parameters like, Lenght of textil, time to weld, cut or weld or both. Possibility of matrix change to preform differents diferent final products. Equipped with an HMI console, it allows the operator to configure production parameters as well as the product to be produced.

- Social Masks / Surgical.

- Scarves.

- Different types of textiles.

- Non-Woven Fabric.

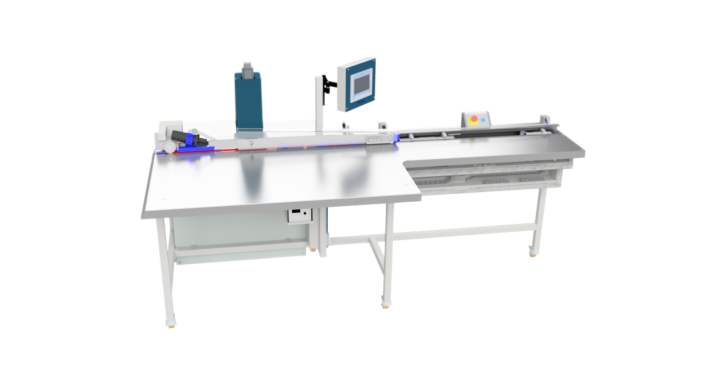

D-CUSW

CONTINOUS ULTRASONIC WELDING

This equipment allows you to program different measures of fabric to be welded, being able to create different types of final product according to customer needs. Possibility of creating references for different products, configurable in each one of them. Equipped with an HMI console, it allows the operator to configure production parameters as well as control the quality of the final product. Automatically adjustable welding system according to material thickness.

- Surgical Gowns.

- Surgical Gowns Sleeves.

- Textiles Sleeves.

- Different types of textiles.

- Non-Woven Fabric.

D-FUWT

FOLDING AND ULTRASONIC WELDING TEXTIL

The Ultrasonic Welding Textil, D-UWT allows you to program the size of the fabric to be cut or weld, being completely flexible in process and parameters of the cutting and welding, it can create different types of products according customers needs. It is possible to create more than 20 references, changing the parameters like, Lenght of textil, time to weld, cut or weld or both. Possibility of matrix change to preform differents diferent final products. Equipped with an HMI console, it allows the operator to configure production parameters as well as the product to be produced.

- Social Masks / Surgical.

- Textile Belts.

- Different types of textiles.

- Non-Woven Fabric.

- Elastic Bracelets.

- Elastic Ribbons.