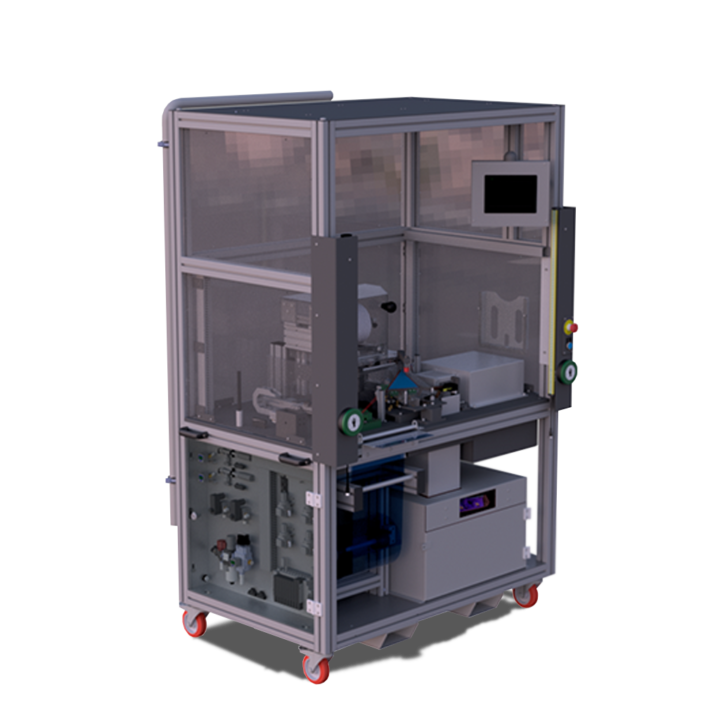

BFDB

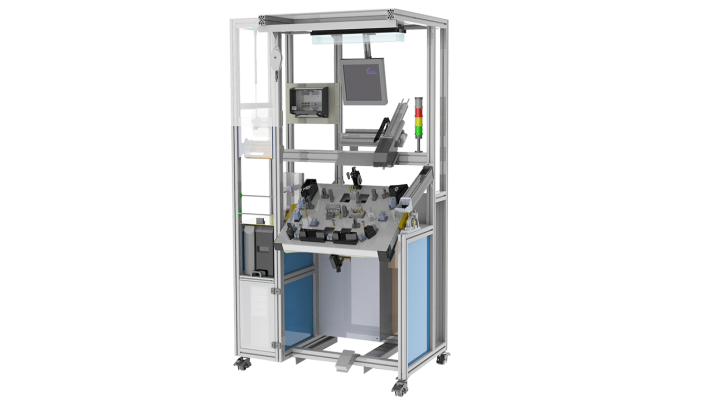

BOLTING SYSTEMS – BATTERY BOX

Product specially developed for bolting terminals in its position in the box and verification of presence of components by artificial vision.

- Selection of the type of product by bar code

- It ensures terminal bolding in the right place

- Bolting with torque and angle control

- Electrical continuity verification

- Presence control of components by artificial vision

- It can work independently or integrated in other equipment

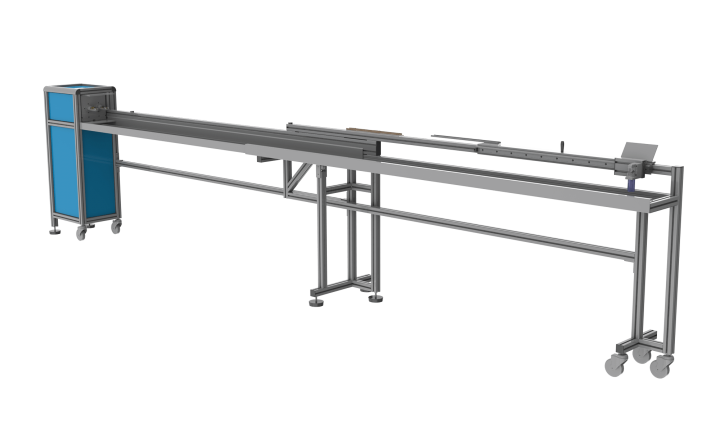

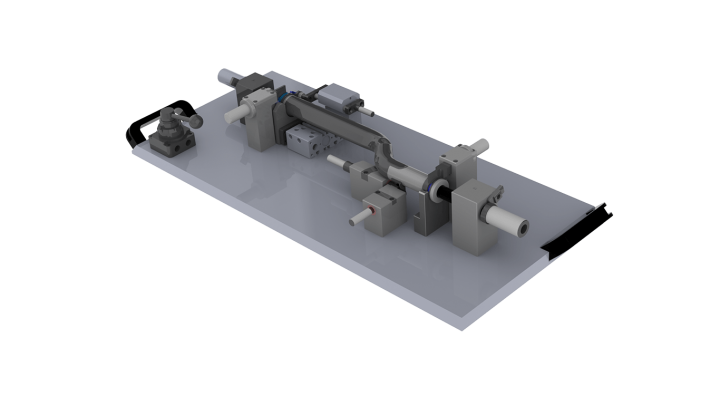

MEF-V2001

TWISTERS - EXPANDABLE

Telescopic machine for wire braid

- 1 workstation

- Number of turns is manually inserted according to wire type

- 2 winding heads capable of braiding 2 or 3 wires per head

- It has the capacity of braiding simultaneously 2 wire sets of the same type

- Easy wire block on the head

- Wire Pneumatic block in car compensation

- Dimensions: 500 x 3750 to 6100 mm

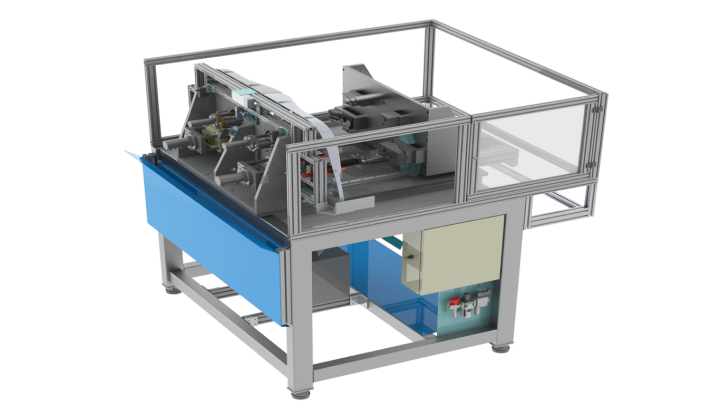

PORTEUR AV

CUT EQUIPMENTS - PLASTIC

Equipment specially designed to make several holes on the door panel.

- It enables drilling operation on two door panels (right and left)

- After several cuts, the piece is taken out of the cut equipment by a robot

- Cuts are made by a system with 4 hydraulic cylinders and cuttings in hardened steel

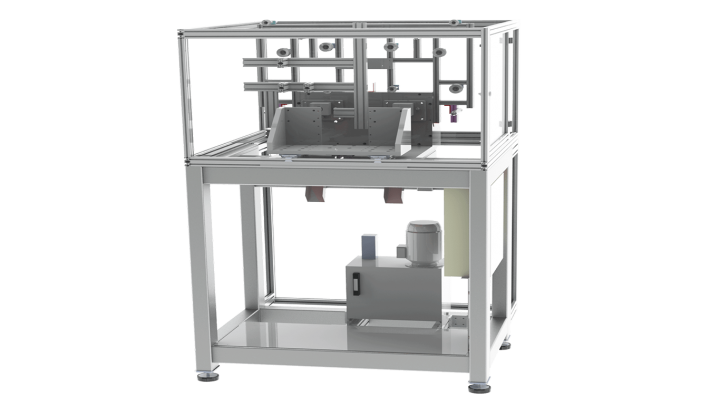

PORTEUR AR

CUT EQUIPMENTS - PLASTIC

Equipment specially designed to make several holes on the door panel.

- It enables drilling operation on two door panels (right and left)

- After the removal of the pieces from the injection machine, they are placed in the equipment by a robot

- Cuts are made by a system with 2 hydraulic cylinders and cuttings in hardened steel

- After several cuts, the piece is taken out of the cut equipment by a robot

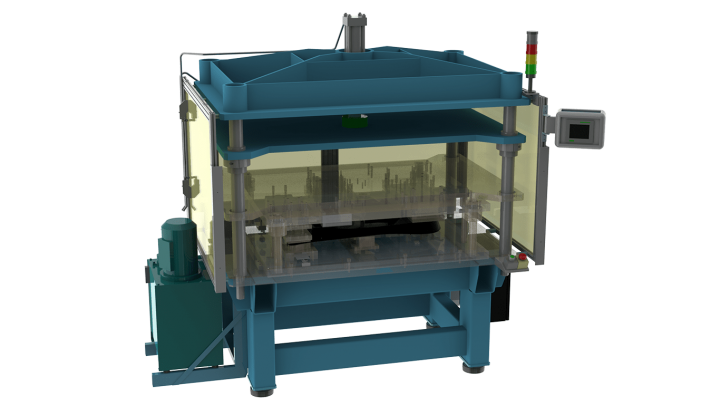

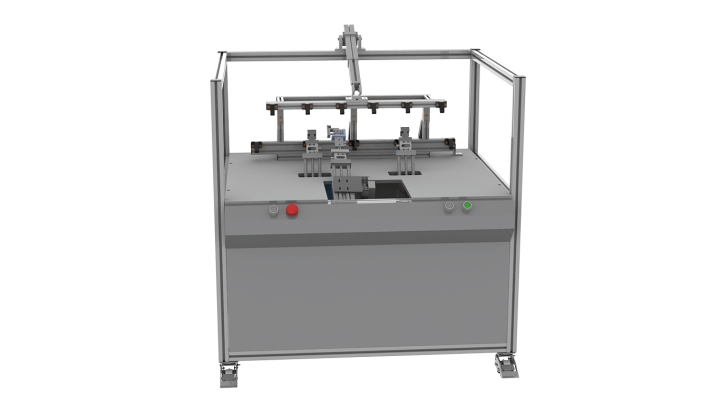

PANEL CUTTING PRESS

CUT EQUIPMENTS - PLASTIC

Hydraulic press developed to make holes in three different panels- Cut tool with all matrices assembled, with activation depending on the version.

- Version selection (1, 2 e 3)

- It has a programming console where images of the cycle of process can be seen

- It has safety barriers that ensure operator’s physical integrity

- Operator’s intervention is required in the beginning and end of the cycle

CONTROL TEMPLATE

CONTROL EQUIPMENTS - GAUGES

“Pass, don’t pass” mechanic calibre for dimensional control.

- Dimensional control

- Position control

PORTEUR AR M3M4

CONTROL EQUIPMENTS - COMPONENTS

Component Control Equipment. Allows the use of the right or left panel through template rotation.

- Checks the existence of different components as well as its position

- Enables bolting with handle door torque control

- Through artificial vision, it checks the type of cloth used on the armrest

- Bar code reader for the reference produced

- Prints the label with the final bar code

AUTOMATIC OPENING (GLOVE COMP.)

CONTROL EQUIPMENTS - FUNCTIONAL

Laboratory equipment for testing glove compartment opening and closing of the car on its normal assembly position.

- Opening and closing test

- Opening time control

- Opening and closing force measure with load cells

- Allows right or left glove compartment testing

- Records read values

- Programming console

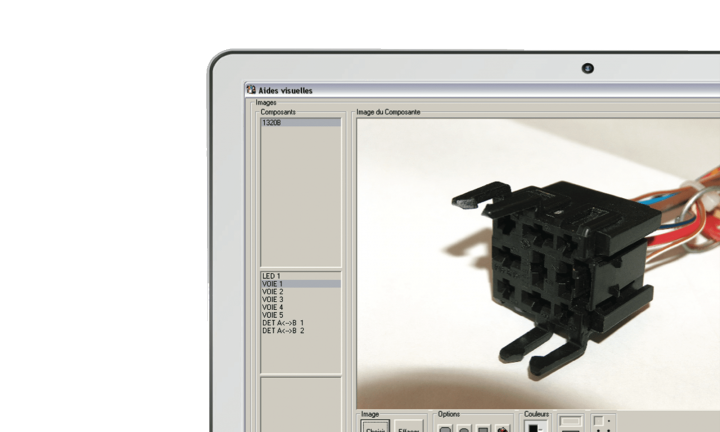

DIVTESTER

SOFTWARE AND HARDWARE

Hardware specially developed for small wiring test.

- All-In-One Test system (Computer and integrated data acquisition unit)

- Up to 256 test points

- 8 inputs e 8 programmable outputs

- Compact metallic box W340 x H170 x D310 mm

- Front panel with numeric keyboard, probe and USB input

- It is programmable with DV-SCAN software or through self-learning

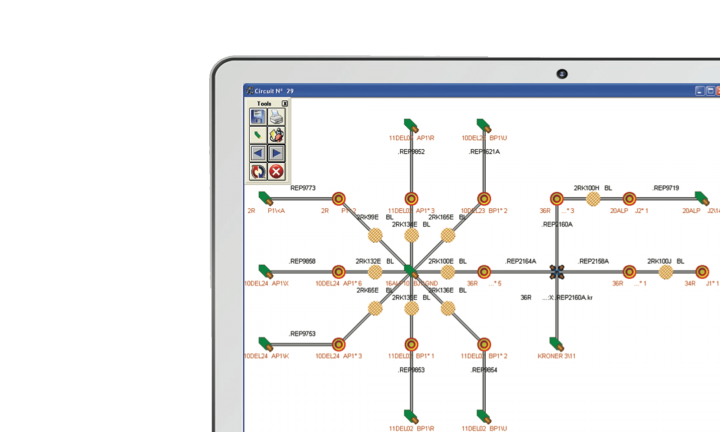

MONCAB/EDCAB

SOFTWARE AND HARDWARE

Software developed for reference and control programming of low voltage test equipments.

- Powerful and intuitive graphic interface for programming and error presentation in different test equipments

- User-friendly and quick learning

- It is possible to implement new requirements according to customer’s specifications

- Excel, txt files convertor and other specific format according to customer’s requests

- Multilingual

DV-SCAN

SOFTWARE AND HARDWARE

Software developed for small wiring programming and control.

- User-friendly and quick learning

- Powerful process editor

- Modular programming

- It is possible to implement new requirements according to customer’s specifications

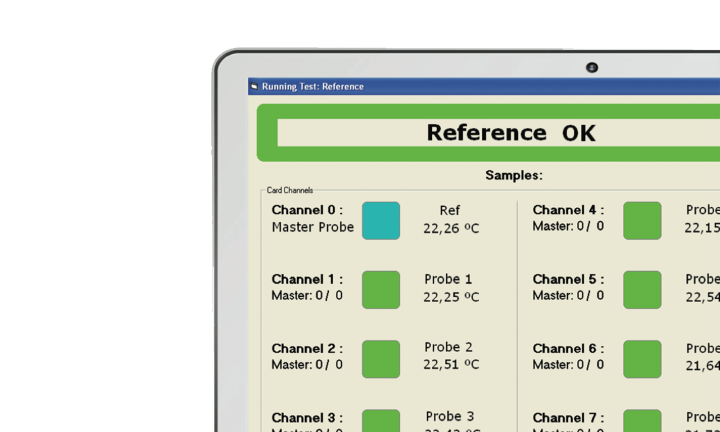

CLIMATE SENSORS

SOFTWARE AND HARDWARE

Software/Hardware for functional test of several sensors involved in climate system.

- Signal reading of the several climate sensors

- Comparison between the Reading and calibres

- Graphical analysis / programming interface

- It is simply programmed/ parameterized

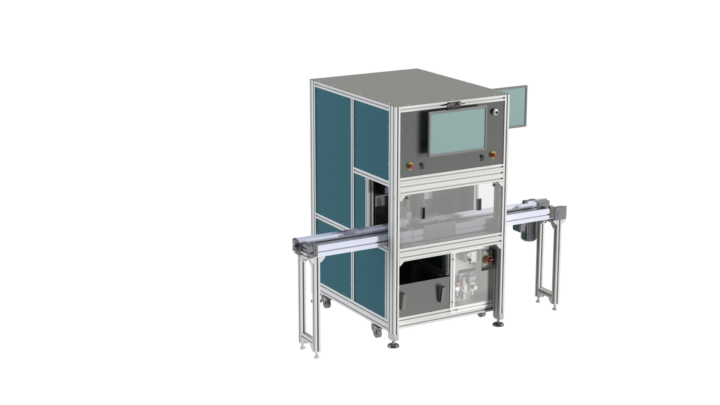

D-IM

AUTOMATIC INSPECTION MACHINE

This equipment could measure the glue height and the continuity of it across the connector groove, allowing total control of the volume of glue applied before the final assembly of the product. This way, were able to increase the quality of the parts produced and reduce the producing costs of defective parts. With the 3D vision software built in-house allows a detailed analysis of the products under test. From a wide range of characteristics to be tested in different type of products, this solution could be applied to any kind of industry or field.

- Control of the Glue and Cutting Process on Objects.

- Control of Volume, Size and Geometry of Objects.

- Quality Control of Different Products.

- Inspection of Defects on Product Surfaces.

- Inspection of Covers Geometries.

D-RC

ROBOT CELL

This equipment is customized according product requirements. Perfectly configurable for different processes and product references. From inter-changeable tools or fixtures, it could work changing it on the running process. All machine components totally customized. From Robot Brands to cell compositions it could be full customized according customer’s need.

- Steel Structure (Different Sizes).

- Safety System.

- Vision Camera System To Visualize The Process In Real Time.

- HMI Console.

- Two Independent Working Zones.

- Different Tools And Fixtures.

- Customized Robot Specifications.

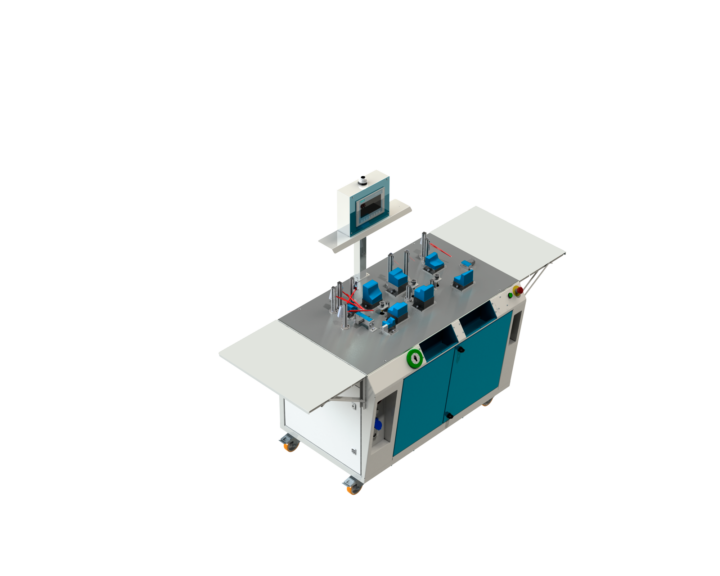

D-SENSOR

DETECTION EQUIPMENT

D-Sensor is a detection system with various types of sensors to detect components in specific parts. The equipment can be adapted to any kind of part, from the simplest geometries to the most complex, irrespective of their dimensions. With fibre optic and capacitive, photoelectric sensors, among others, it is possible to guarantee the detection of an extremely wide range of clips, pads, gaskets and many other components. This type of semi-modular concept makes it possible to set up the equipment and components according to the client’s needs.

- Part-Carrying Base.

- Component Box.

- Control Units.

- Screening Control.

- Detection of Components.

- DSemi-Modular Equipment.

- Ergonomics.

D-SCS 1

SPRUE CUTTING STATIONS

D-SCS is a sprue cutting station used to cut the plastic parts of all shapes and sizes. It is possible to adapt the machine to the customer’s request and to the product that needs to be finished.

- Cutting of sprue made by hot blade with thermal regulator.

- Two stages: one for the sprue cut and second for component control and assembly.

- Cutting sprue for PMMA Material.

- Screening Control.

- Precision of cutting guaranteed.

- Precision of component position -+1mm.

- Ergonomics.

D-SCS 2

SPRUE CUTTING STATIONS

D-SCS is a sprue cutting station used to cut the plastic parts of all shapes and sizes. It is possible to adapt the machine to the customer’s request and to the product that needs to be finished.

- Removable tool – Possibility to work with different tools for different references.

- Cutting sprues of ABS, PP material up to 80mm.

- Removable and independent tool that could work with injection machine robot.

- Pneumatical cold cut system.

- Precision of cutting guaranteed.

- Ergonomics.