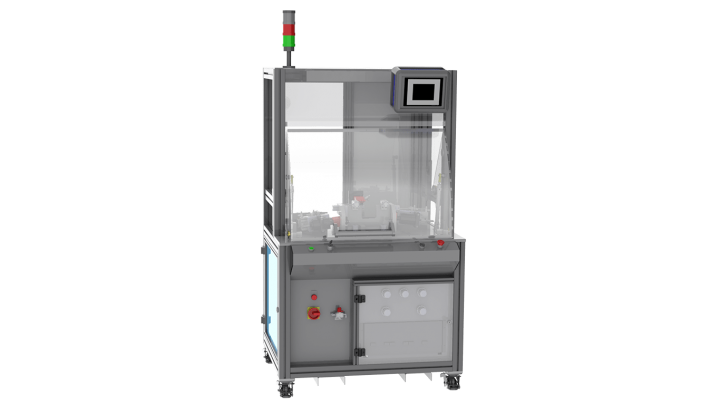

HEADREST

ULTRASOUND WELDING – PLASTIC

This equipment, specially designed for automotive sector. It has as purpose the headrest welding. (plastic component).

- 5 sonotrodes

- Ok warning when the piece is correctly welded

- Frontal protection system

- Console for process control and welding parameters introduction

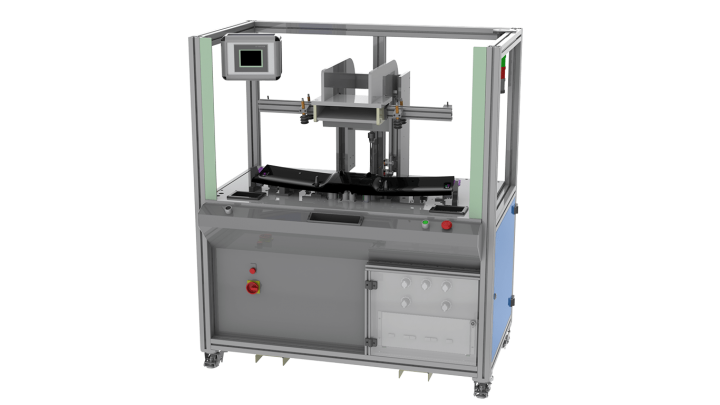

ASM PANEL

ULTRASOUND WELDING - PLASTIC

Equipment developed for ultrasound welding, clips introduction and component assembly verification.

- Based on 2 generators and 5 sonotrodes.

- Automatic system that withdraws the piece from welding area

- Programming console where all further steps can be seen.

- Safety barriers regarding operator’s protection

PILAR C L/R A3

ULTRADOUND WELDING - PLASTIC

Equipment specially developed for automotive sector. Its main function is regarding right and left piece ultrasound welding on the Audi A3. It is required to have two operators working simultaneously in the same equipment, opposite to one another.

- Based on 4 generators and 6 sonotrodes

- Time programming consoles with all welding steps, from the placement of the piece to its finishing.

- Safety barriers regarding operator’s protection

- Bar code readers

MOLD PARTS 7157

ULTRASOUND WELDING - PLASTIC

Equipment developed for ultrasound welding and it operates simultaneously in left and right parts.

- Based on 9 welding sonotrodes placed on top position

- 3 generators

- Parameter control console

- Safety barriers regarding operator’s protection

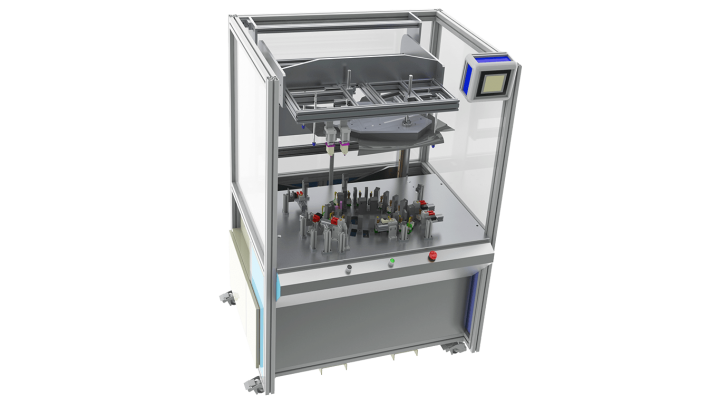

COSTADILLO SE250

HOT SPOTS WELDING - PLASTIC

Equipment for hot spots welding on door panel.

- 19 hot spot weldings

- 2 metallic clips introduction

- 6 plastic clips introduction

- Safety barrier

- Panel block by the decrease of the greater amount

- Parameterization console and the sequence of operations can be displayed