Divmac has developed valuable skills which enables the conception of innovative solutions, focused on fulfilling customers’ needs, in order to increase the effectiveness and efficiency of manufacturing processes as well as quality assurance. It provides a wide range of products, especially intended for quality control in compliance with customers’ requirements.

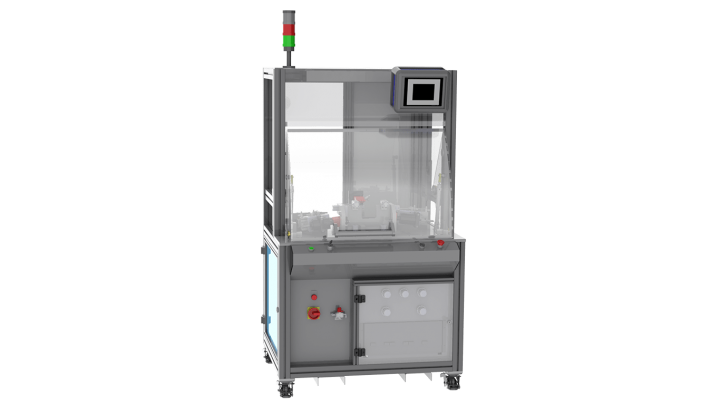

Testing Systems: Wiring

MTE-99 (2 PLANES)

Product developed for wiring test. Aspects related to ergonomics, ease of movement and handling for the proper transport of equipment were considered in its conception. This equipment may be developed according to the client’s request.

Testing Systems: Auto radios

FTC50

Equipment developed to test LCD’s vision angle from car radios.

Assembly Cells

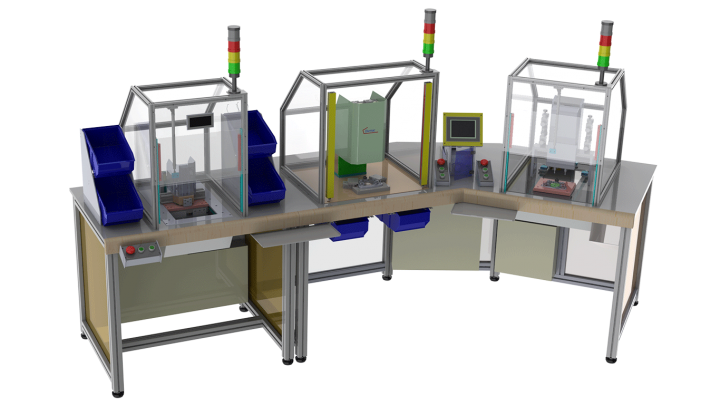

REACTION PLATE

Equipment developed for spring assembly and ultrasound welding. Its main objective is to check airbags. It has a console for parameters introduction.

Ultrasound Welding

HEADREST

This equipment, specially designed for automotive sector. It has as purpose the headrest welding. (plastic component)

Special Machines

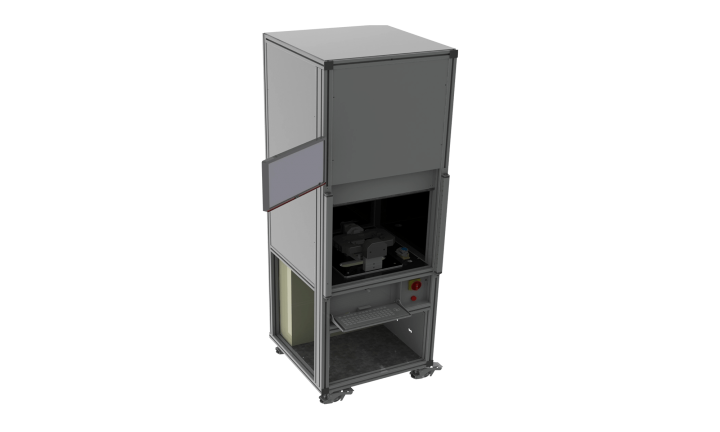

BFDB

Product specially developed for bolting terminals in its position in the box and verification of presence of components by artificial vision.

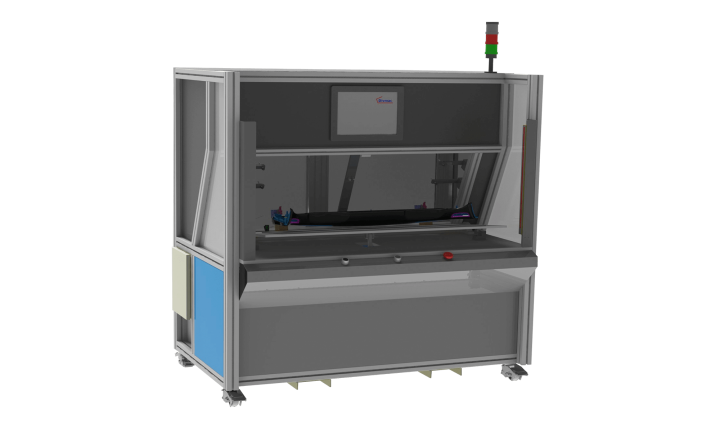

Artificial Vision

VW GOLF CABRIO

Equipment designed regarding the verification of the existence of components and its assemblage by artificial vision. The system enables the exchange of the inserted pieces in order to work in different panels.